ABOUT US

SCOPX LABS was founded by Marijan Fofonjka on June 2, 2018. The goal of SCOPX LABS is to offer solutions to solve quality and monitoring problems within the manufacture of springs and other industries, meeting customer requirements. The products and services provided by SCOPX LABS are based on advanced technology and are easy to use. SCOPX LABS is a member of EtherCAT Technology Group (ETG).

OUR PRODUCTS

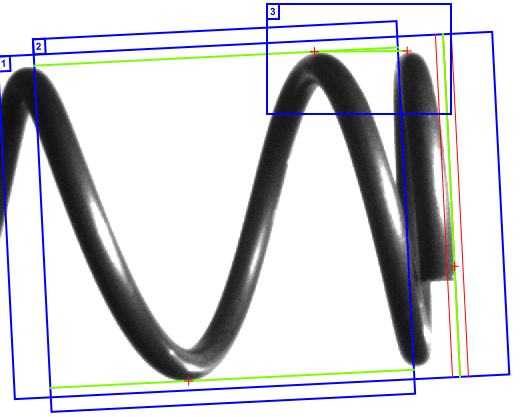

SPRING COILING PROCESS CONTROLLER

System for examining the length, diameter, and pitch of springs directly on the machine during the production process. The system sends a signal to the machine, which automatically corrects the production process for the chosen part. Thanks to its own processing unit, the system does not overload the coiling machine and guarantees the smooth operation of the entire solution.

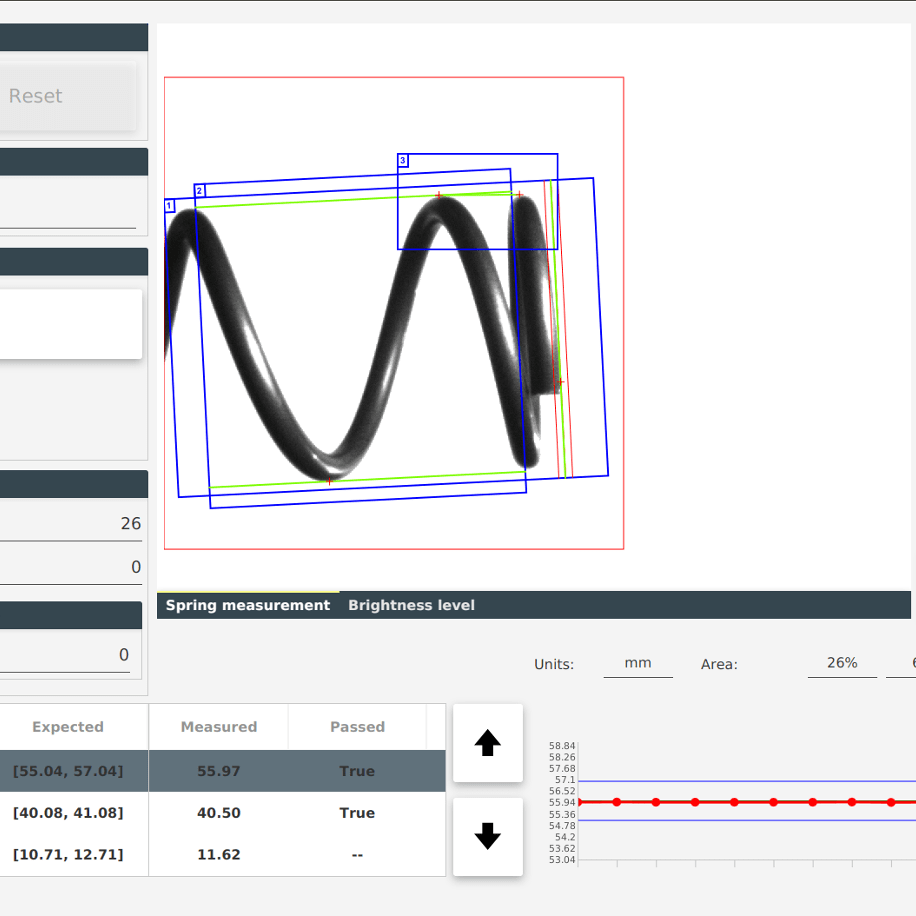

SPRING MODEL MEASURER

System that measures the dimensional characteristics of the springs, such as their free length, diameter, and pitch. Scanned mesh models can be automatically compared with a reference 3D model of the spring and exported to standard formats compatible with other software. The measured dimensional characteristics can be exported as a PDF report.

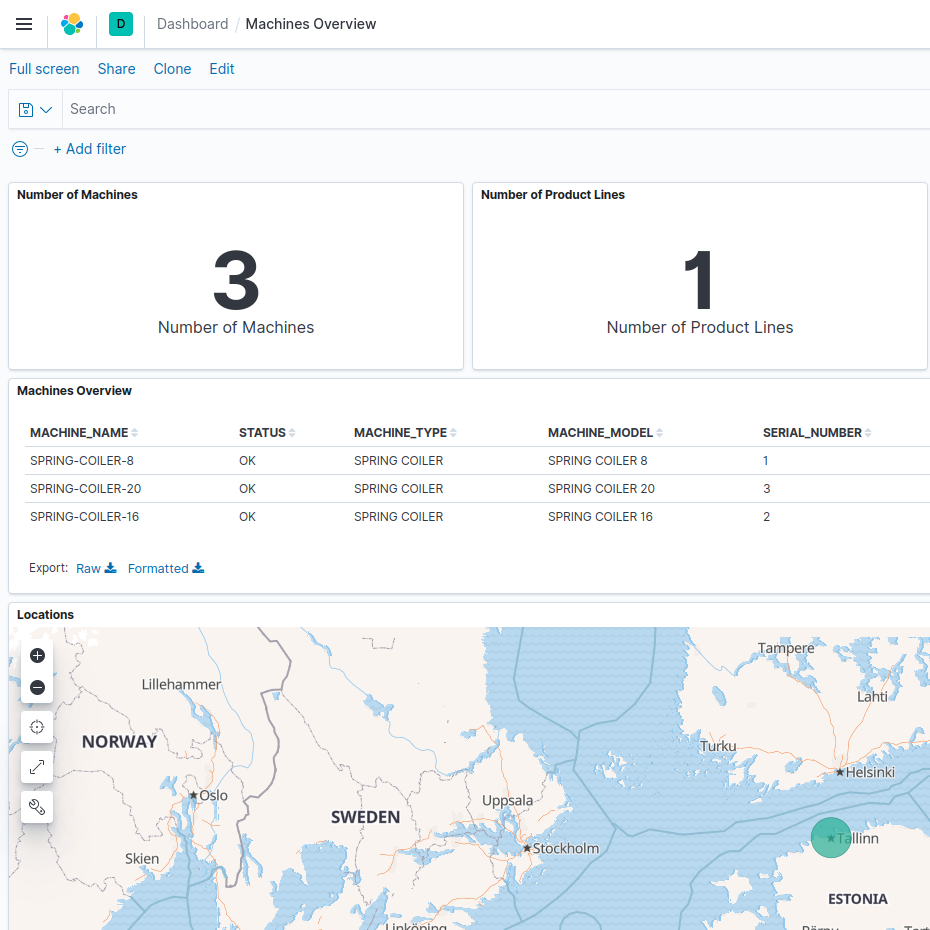

PRODUCTION CONTROL

Monitor all machines on your production lines in one central place from anywhere. Automatically identify issues before they become outages. Generate real-time reports and save them in secure, read-only formats such as PDFs. Utilize Machine Learning to estimate future parameters of your production process.

CUSTOM SCOPX LABS SOFTWARE SOLUTIONS

By monitoring your machine performance, you can identify malfunctions. By fixing these errors, you can increase your output and the quality of your products. Reduce tolerance fluctuations in the production process to minimize scrap and improve product quality. This way, you can strengthen your market position significantly.

OUR TEAM

SCOPX LABS are an independent, one-stop creative specialists with the experience and know-how to develop effective business solutions and bring them to fruition.

MARIJAN FOFONJKA

Senior Software Engineer & Solutions Architect

Founder & CEO

CONTACT US

EMAIL ADDRESS

[email protected]PHONE NUMBER

+385981703069WORKING HOURS

Monday - Friday | 8 am - 5 pm CEST